sujeet rai

Honeycomb Sandwich Material Market Share, and Trends Report 2025-2033

Global Honeycomb Sandwich Material Industry: Key Statistics and Insights in 2025-2033

Summary:

- The global honeycomb sandwich material market size reached USD 1.8 Billion in 2024.

- The market is expected to reach USD 2.5 Billion by 2033, exhibiting a growth rate (CAGR) of 3.37% during 2025-2033

- North America leads the market, accounting for the largest honeycomb sandwich material market share.

- Aluminum holds the majority of the market share in the material type segment due to its ability to offer resistance to corrosion and high temperatures.

- Expansion exhibits a clear dominance in the honeycomb sandwich material industry.

- Aerospace remains a dominant segment in the market, as it requires high-strength and durable components that can withstand extreme environmental conditions.

- The rising utilization in the construction sector is a primary driver of the honeycomb sandwich material market.

- Technological advancements in material production methods are reshaping the honeycomb sandwich material market.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/honeycomb-sandwich-material-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Industry Trends and Drivers:

- Growing Aerospace Demand:

The honeycomb sandwich material market is growing fast. The aerospace industry drives this demand for lightweight and strong solutions. Airlines and manufacturers want fuel efficiency and lower emissions. Honeycomb structures are now common in aircraft interiors, panels, and flooring. Their high strength-to-weight ratio and durability suit modern aviation needs. As air travel increases after the pandemic, demand for these materials will grow with new aircraft designs. This trend opens up great opportunities for suppliers and innovators.

- Sustainability Drives Adoption:

Sustainability trends are changing the honeycomb sandwich material market. Industries want eco-friendly options instead of traditional composites. Honeycomb structures use recyclable materials like aluminum, Nomex, and thermoplastic cores. This aligns with circular economy goals. Manufacturers in automotive, construction, and packaging are adopting these materials. They aim to meet strict environmental rules and consumer demand for green products. This shift speeds up R&D in bio-based cores and reusable designs. Honeycomb materials are becoming a key part of sustainable industrial solutions.

- Cost and Performance Balance:

Honeycomb sandwich materials perform well, but cost is key in the market. New production technologies, like automated fabrication and scalable manufacturing, lower costs. They also make access easier. Industries like marine, wind energy, and transportation use these materials. They value them for their strength and corrosion resistance. As competition grows, suppliers are working on reducing costs while maintaining quality. This makes honeycomb solutions appealing for mid-tier applications and new markets.

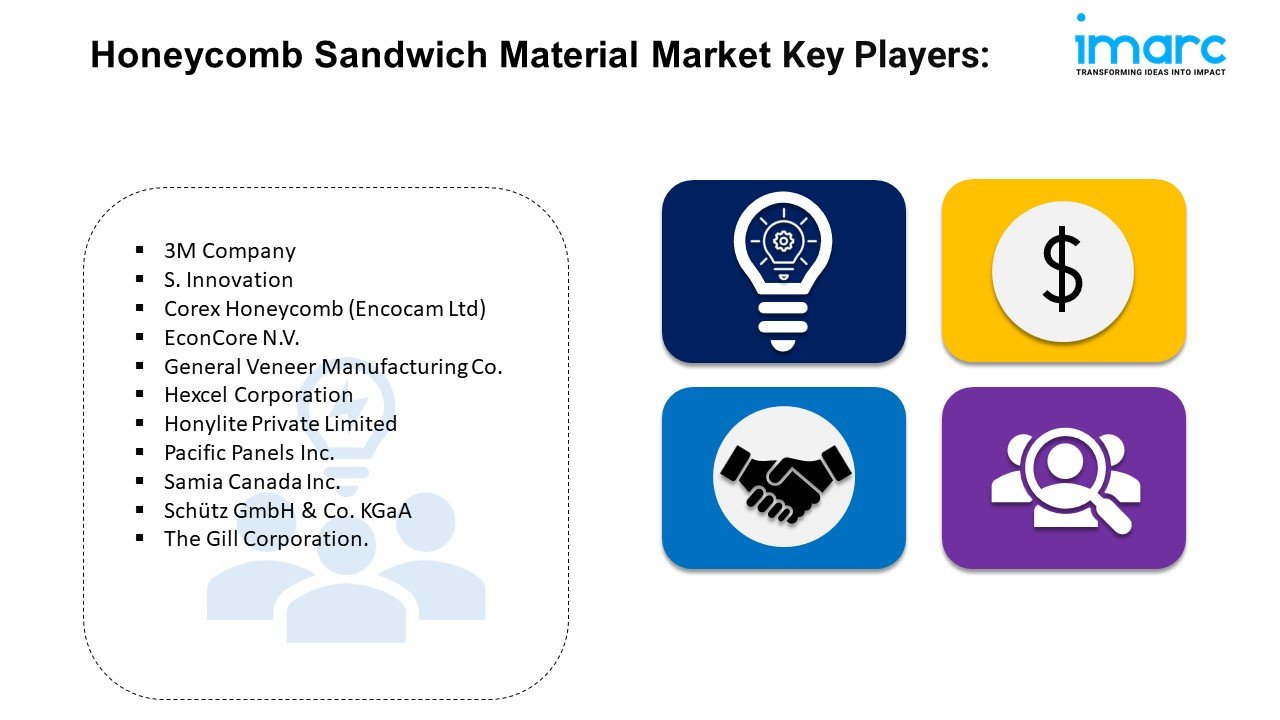

Leading Companies Operating in the Global Honeycomb Sandwich Material Industry:

- 3M Company

- S. Innovation

- Corex Honeycomb (Encocam Ltd)

- EconCore N.V.

- General Veneer Manufacturing Co.

- Hexcel Corporation

- Honylite Private Limited

- Pacific Panels Inc.

- Samia Canada Inc.

- Schütz GmbH & Co. KGaA

- The Gill Corporation.

Honeycomb Sandwich Material Market Report Segmentation:

Breakup By Material Type:

- Aluminum

- Steel

- Composites

- Titanium

- Inconel

- Others

Aluminum represents the largest segment due to its excellent strength-to-weight ratio and widespread use in aerospace and automotive applications.

Breakup By Technology:

- Expansion

- Corrugation

- Molding

- Extrusion

- Others

Expansion accounts for the majority of the market share as it allows for the efficient production of lightweight and high-strength honeycomb cores.

Breakup By Application:

- Aerospace

- Automotive

- Marine

- Locomotive

- Construction

- Others

Aerospace exhibits a clear dominance in the market because of the rising demand for lightweight materials in this industry to enhance fuel efficiency and structural integrity.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America enjoys the leading position in the honeycomb sandwich material market owing to its established aerospace and defense industries and significant investments in advanced manufacturing technologies.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

by sujeet rai on 2025-05-08 04:50:35

No comments yet.