pipingmaterial

Different industries are moving from using stainless steel bars in 2025 to utilizing Duplex Steel Bars. Companies now prefer Duplex Steel Bars because they need stronger steel products that fight corrosion effectively for longer lives. Utilizing duplex steel allows it to combine austenitic and ferritic metallic arrangements. This product stays effective in challenging situations. Companies across multiple industries now use duplex instead of standard stainless steel because of its advantages. Through this article we will explain why organizations are choosing Duplex Steel instead of traditional alternatives today.

Higher Strength Without Extra Weight

Companies embrace Duplex Steel Bars mainly because they deliver stronger performance. These bars provide 100% more strength than regular stainless steel bars. The product will deliver its intended performance with less material required. Using this method saves weight and money on big projects.

Projects with big steel structures benefit greatly from this upgrade. Using the duplex metal instead of stainless steel permits engineers to produce weight-saving yet robust frame systems. Constructors and offshore... More

by pipingmaterial on 2025-04-26 01:11:15

The metal Inconel handles both extreme heat and corrosive substances nobly. The power, chemical, marine, and aerospace sectors widely use Inconel due to its excellent performance. Inconel Sheet holds its structural integrity under extreme environmental conditions. The advantages of Inconel depend on finding a reliable supplier to buy from. Working with improper suppliers leads to receiving weak materials at elevated prices. This blog shows the proper ways to find Inconel sheets for demanding projects.

Always Verify Material Certification

Begin evaluation by confirming if the supplier delivers complete material verification documents. The certified Inconel Sheet includes testing documents showing exact composition and performance specifications. Having this information ensures safety because it determines if Inconel will withstand extreme heat and pressure conditions.

These suppliers follow industry standards similar to those practiced by top Stainless Steel Fittings producers and Stainless Steel Flanges producers when providing documentation. The documents verify that your purchase conforms to global standards and can operate safely within your operational... More

by pipingmaterial on 2025-04-12 02:02:10

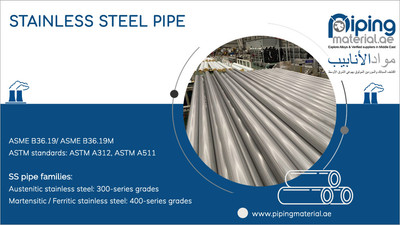

Are you looking for the best SS Pipe suppliers? You must consider features like cost efficiency, reliability, and durability. Since stainless steel has excellent corrosion resistance, various industries use itÑfor instance, in construction, food processing, and drug production. One must understand the ability of the suppliers when choosing different types of SS products to meet their specific project requirements.

Here is a comprehensive guide to help you make the right choice when choosing SS PIPE suppliers.

1. Consider your project needs

Before choosing an SS PIPE supplier, it is important to understand the specific requirements of your project. Think of factors such as the environment where pipes will be used (eg in contact with high pressure, temperature or corrosive elements) and required physical properties (e.g. strength and corrosion resistance). Different SS materials, such as 304, 316 or duplex stainless steel, offer different degrees of resistance to corrosion, strength and performance under extreme conditions.

If your project requires resistance to rust and tough conditions, Duplex Fittings or choose for high-quality stainless steel pipes offer long-lasting... More

by pipingmaterial on 2025-03-03 03:34:59

Duplex metal is widely popular among industries for corrosion resistance and flexibility. Therefore, they are the best choice in oil and gasoline, petrochemical, and marine engineering science industries. Various duplex steel components, bolts, pipes, plates, flanges, and rods are utilized in tasks requiring durability and performance. Let’s explore in detail:

1. Duplex bolt: Strength and rust resistance in bondage

Duplex bolts are made of stainless steel with austenitic and ferritic microstructure. The combination of duplex bolts provides better power and corrosion resistance and, therefore, high reliability in extreme environments. Such duplex bolts are highly used in very stressed environments with corrosive environments, like offshore platforms or chemical processing facility plants.

Duplex bolts are robust and best for heavy-duty applications that require the fastening process to be done securely. They also provide great resistance to pitting, crevice corrosion, and stress corrosion cracking, making them a first option for industries that demand high-performance materials.

2. Duplex Pipe: Performance in Harsh Environments with Reliability

Duplex... More

by pipingmaterial on 2025-02-25 08:13:40

In selecting materials for usage in industrial projects, durabilty is one of the greatest considerations, especially resistance to corrosion. Inconel plate is among the most outstanding alloys which are used in combating corrosion in environments where temperatures are high or are generally extreme. This nickel-chromium superalloy, is applied frequently now in aerospace industry, chemical industry and power industry etc. But there are many Inconel plates out there, choosing the right one for your project is crucial when it comes to the best quality, durability and performance.

1. Identify the Corrosive Elements in Your Environment

To select the right Inconel plate for corrosion resistance, you need to determine certain corrosive factors within the environment. The various grades of Inconel are aligned with differences in their capacities to tackle various forms of corrosion. For instance, if your project requires you to use spilage sulfuric acid, or spilage hydrochloric acid, then you will appreciate that Inconel 625 is highly resistant to these tough chemicals.

Likewise if your project is exposed to high heat and oxidising conditions then Inconel 600 could... More

by pipingmaterial on 2024-12-14 12:20:51

There is no arguing that threaded pipe fitting is an integral part of production processes in companies that need reliable joints. But how do these manufacturers ensure that their quality is so high?

It entails close supervision, high technology equipment, and more testing than any other mode of production. Thus, all the steps are done very cautiously and, therefore, there are no faults within the execution of the agencies. It is very essential to note that such industries cannot afford to be slack, even when a failure may only be tiny, it may lead to catastrophic occurrences. This blog will explain to you how threaded pipe fittings manufacturers go about it in order to conform to international standards.

Using High-Quality Materials

The requirements of quality maintenance can be initiated by selecting materials for production, itself. Some of the common materials which manufacturers use on the production of the tools include stainless steel, carbon steel as well as brass. Stainless steel is more preferred due to its non-corrosive and pressure taking nature. While there are many SS Pipe Fittings suppliers, quite a few of these suppliers also offer superior... More

by pipingmaterial on 2024-12-13 11:36:36

Choosing the appropriate MS Plate suppliers for the specific Project work is one of the most important decisions in construction or manufacturing industry. With high tensile strength, and overall considerably low cost, mild steel (MS) plates are used in construction, engineering, and manufacturing industries. However, not all MS plate suppliers are the same as in this world, there are varying qualities and types of MS plates.

1. The Quality of Material and Standards

The quality of the MS plates is one of the most important things to look at when choosing the MS Plate suppliers. Precise specifications are not met when manufacturing steel plates. Superior Grade MS plates are of substantial tensile strength and are capable to meet the pressure of the project. Search for suppliers who provide materials that have an international standard. For instance, most of the industries need Monel plate or Inconel plate because both are strongly protected and resistant to corrosion. Some of these plates are made with special high-performance alloys ideally used in harsh environments.

There should also be some conditions that guarantee high quality; so, when dealing with... More

by pipingmaterial on 2024-12-03 01:20:46

There is no arguing that threaded pipe fitting is an integral part of production processes in companies that need reliable joints. But how do these manufacturers ensure that their quality is so high?

It entails close supervision, high technology equipment, and more testing than any other mode of production. Thus, all the steps are done very cautiously and, therefore, there are no faults within the execution of the agencies. It is very essential to note that such industries cannot afford to be slack, even when a failure may only be tiny, it may lead to catastrophic occurrences. This blog will explain to you how threaded pipe fittings manufacturers go about it in order to conform to international standards.

Using High-Quality Materials

The requirements of quality maintenance can be initiated by selecting materials for production, itself. Some of the common materials which manufacturers use on the production of the tools include stainless steel, carbon steel as well as brass. Stainless steel is more preferred due to its non-corrosive and pressure taking nature. While there are many SS Pipe Fittings suppliers, quite a few of these suppliers also offer superior... More

by pipingmaterial on 2024-11-25 05:13:01

When handling aspects of piping systems, you need to ensure that you are familiar with the standard that concerns flanges as well as fittings. ASME B16.5 is one of the most employed standards that are used on flanges and pipe fittings. This standard includes the geometric design of flanges and fittings from steel and classifies the pressure of the said material for employments in different industries.

1. What is ASME B16.5?

ASME B16.5 is one of the most specified standards by the American Society of Mechanical Engineers for flanges and related products for piping system. Such a rating applies to flanges that are carbon steel, alloy steel, and stainless steel flanges. This standard addresses several areas such as flange size, pressure temperature characteristics, material and construction features and fabrication procedures. It is a guarantee that flanges and fittings can withstand the pressure and temperature range that is characteristic of industries.

2. Why is ASME B16.5 Important?

There are several reasons for the relevance of ASME B16.5 because it helps to control the safety, reliability, compatibility of the elements of the pipe system. It establishes the most basic... More

by pipingmaterial on 2024-11-25 03:45:21

When contractors select substances for metal pipework, stainless steel is regularly ignored because of its fee in comparison to different options which includes PVC for programs along with wastewater and chemical shipping. But the numerous advantages of stainless steel pipe for commercial and commercial application make this a cloth that offers price and return on investment.

- Stain and corrosion resistant

Corrosion is the main enemy of metal piping. The outer floor of metal, iron and stainless steel pipe fittings can degrade from soil and UV mild. Interior partitions of piping crafted from other substances will generally tend to rust, are damaged via abrasion, or acquire particles. But way to the corrosion resistance homes of stainless-steel, this is some distance much less not unusual. This offers chrome steel the threshold on the subject of applications like sanitary water transport or sanatorium applications.

When you operate stainless steel sheet, you're shopping for a long lasting product in an effort to last your commercial enterprise for decades. It is a reliable fabric that is simple to maintain and install. Stainless metallic is low-upkeep, and due... More

by pipingmaterial on 2024-11-25 03:31:23